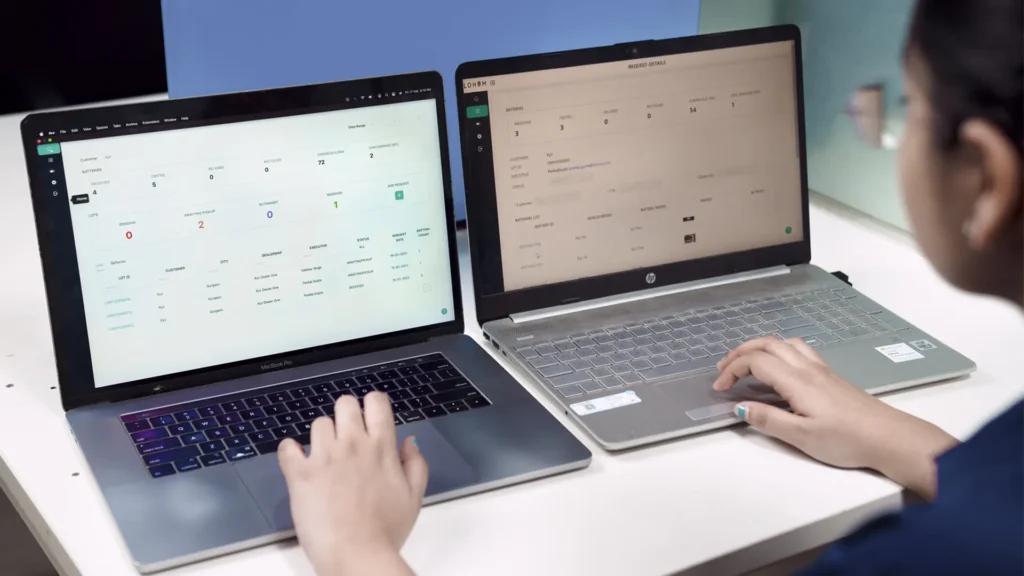

Lithium Ion Battery Raw Materials: Our Zero Waste Approach

At LOHUM, we recycle Lithium-ion batteries of all cell chemistries and form factors via our hydrometallurgical NEETM™ technology. We safely recover black mass and process it to extract and isolate high-purity metal sulfates and carbonates ready for use in cathode and precursor production.

LOHUM creates a circular economy in the Li-ion battery ecosystem by recirculating raw materials back into the supply chain, significantly improving both the environmental benefits and economic sustainability of batteries. NEETM™ enables us to recover 95% of all Li-ion metal salts at 50% lower CO2e than mining.